Business

Silver Prices Sink Sharply To Rs 2.25 Lakh/Kg On MCX, Log Biggest One-Day Fall In 4 Years; Know Why

Last Updated:

Silver is the big mover in trade overnight. Prices have finally stabilised after slumping 8.7% in the biggest one-day fall since August 2020

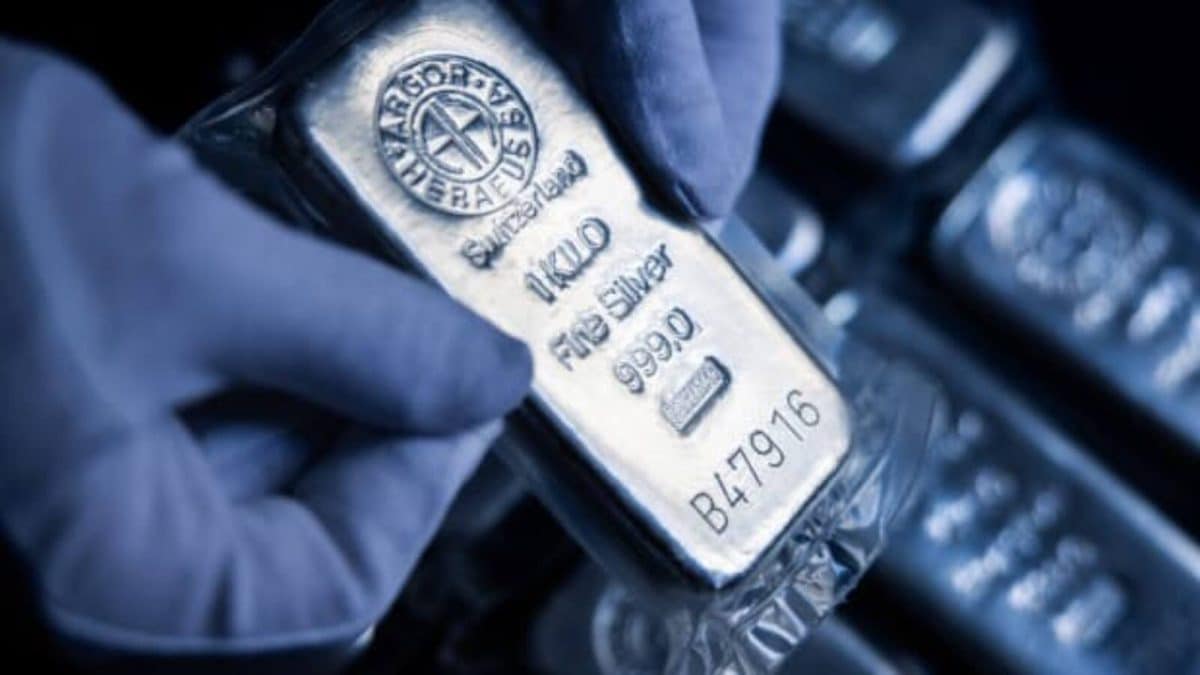

Silver Prices Fall

Silver Prices Crash: Silver is the big mover in trade overnight. Prices have finally stabilised after slumping 8.7% in the biggest one-day fall since August 2020. In fact, the year-end is proving to be highly volatile for silver. On MCX too, silver prices plunged to the Rs 2.25 lakh/kg level from a high of Rs 2.54 lakh/kg.

Most analysts believe that this correction in prices may have helped bring down some of the speculative trade in silver.

Let us look at the price rates of silver in different cities of India

Prices in India correct in sync with global trend

MCX silver prices generally follow global silver prices, moving in line with COMEX trends and currency changes.

Currently, silver prices in India are down 0.04%, with one kg trading at Rs 2,33,480/kg, while the price of 10 gram silver today is Rs 2,334.80.

For city-wise rates, the white metal is trading at Rs 233.76 per gram in Mumbai, followed by Delhi, where the silver rate is Rs 223.21 per gram, which is Rs 10.27 lower than the silver rate in Mumbai.

The silver rate in Chennai is Rs 224.25 per gram, while the silver rate in Hyderabad is Rs 223.95 per gram. The silver rate in Ahmedabad is Rs 223.89 per gram.

These differences in city-wise prices mainly arise from local taxes, transportation costs and demand levels.

So what exactly is driving these prices? Let’s take a look at the key triggers for the sharp correction in silver prices:

1. Aggressive profit booking

Analysts added that aggressive profit booking by traders led to a crash in the prices of the white metal. Traders sold silver to lock in gains as prices had spiked. Further, trading volumes in the markets are relatively low because of the holiday season, which made silver rally higher than usual.

Commenting on the volatility, Jigar Trivedi, Senior Research Analyst at Reliance Securities, said, “Silver rose 2.6% to $73.9/oz, stabilizing after a steep drop in the previous session, as traders adjusted positions following aggressive profit-taking. The rebound follows a sharp retreat from record highs above $80 an ounce, with holiday-thinned liquidity amplifying recent price swings.”

2. CME raises margins

Margin costs raised by the CME Group compelled traders to reduce their market positions, triggering a sell-off. The exchange hiked margins for the March 2026 derivatives contract to $25,000 from $20,000 earlier.

This essentially means traders now have to pay more to keep their contracts. Often, margin hikes are used by exchanges as a risk-control tool to manage volatility.

“Stricter margin rules may keep price gains measured in the short term. MCX Silver March may appreciate to Rs 226,000/kg as the undertone is bullish in the international markets,” Trivedi added.

3. Easing geopolitical tensions

The meeting between US President Donald Trump and Ukrainian President Volodymyr Zelenskyy has eased geopolitical tensions between Russia and Ukraine, as both leaders said an end to the war is close. The Ukrainian president views the peace plans as 90% agreed following talks with Trump.

Easing geopolitical tensions ultimately reduce safe-haven demand for precious metals, thereby lowering demand.

Silver rally: Next target?

According to MOSL, silver price rally is rooted in real metal scarcity and is not just speculative.

It explained that beyond supply constraints, sustained industrial and investment demand has reinforced silver’s price strength. Its growing use in electronics, renewable energy and other technology-driven sectors has ensured steady industrial offtake, while investors have increasingly viewed silver as a strategic hedge amid macroeconomic uncertainty.

Navneet Damani and Manav Modi, Commodities Analyst at MOSL noted, “Silver’s 2025 rally is being shaped by real metal scarcity rather than speculative positioning. Physical deficits, policy-driven supply restrictions, and concentrated inventories are increasingly dictating prices, signalling a durable shift in how the silver market is priced and traded.”

From an investment perspective, MOSL said it continues to maintain a buy-on-dips approach with a staggered investment strategy. While its initial target of $75 on COMEX has already been achieved, the brokerage reiterated its next target of $77 on COMEX, equivalent to around Rs 2,46,000 in the domestic market. Any further revisions to this outlook, the report noted, will depend on how supply dynamics, inventory trends and policy developments evolve over time.

December 30, 2025, 10:52 IST

Read More

Business

Why you should consider switching bank accounts

Martin Lewis explains why now might be a good time to think about changing your bank account.

Source link

Business

Video: The Hidden Number Driving U.S. Job Growth

new video loaded: The Hidden Number Driving U.S. Job Growth

By Ben Casselman, Christina Thornell, Christina Shaman, June Kim and Nikolay Nikolov

February 13, 2026

Business

How packaging and logistics companies are automating their warehouses

DHL Autonomous Robot at work.

Source: DHL

Workers at DHL Group used to walk close to a half marathon each day just to classify, pick and move items across massive warehouses.

Now, their distance and efforts are greatly reduced by autonomous mobile robots that can unload containers for the package delivery and supply chain management company with a speed of up to 650 cases per hour.

“That is what we look forward to, and where we’ve been successful in deploying technology at scale over the last five years, going from when we started in 2020 with 240 projects, and now we’re up to 10,000 projects,” Tim Tetzlaff, DHL’s global head of digital transformation, told CNBC.

The company’s autonomous innovations have accelerated processes at 95% of DHL’s global warehouses. Item-picking robots in one warehouse have increased units picked per hour by 30%, while autonomous forklifts at that same warehouse have contributed a 20% increase in efficiency, the company said.

Tetzlaff said automation is important for the company because it’s such a labor-intensive business.

“We still have the ambition to grow our business even further, but if you look at where these distribution centers should be located … it’s typically very tough to find additional labor or even additional spaces just to build these warehouses there,” he said.

DHL is one of multiple fulfillment companies moving toward automation and leveraging artificial intelligence as the industry works toward greater efficiency.

On an earnings call with analysts in late January, United Parcel Service CEO Carol Tomé said the company deployed automation in 57 buildings in the fourth quarter, bringing its total to 127 automated buildings, with plans for 24 more in 2026.

“This year, we plan to further automate our network and as a result, we expect to increase the percentage of U.S. volume we process through automated facilities to 68% by the end of the year, up from 66.5% at the end of 2025,” she said.

Similarly, FedEx has said it sees automation as an opportunity to enhance its workers’ jobs, installing robotic arms to help process small packages at its Memphis hub and working with AI company Dexterity to leverage robots for loading boxes into containers. Its “Network 2.0” initiative is working to increase the efficiency of its package processes.

The company recently announced a partnership with Berkshire Grey to launch a fully autonomous robot to unload containers and optimize operations.

It estimates that the global warehouse automation market is expected to exceed $51 billion by 2030.

“We now have about 24% of our eligible average daily volume flowing through 355 Network 2.0-optimized facilities,” CEO Raj Subramaniam said on a call with analysts in December.

A human fleet

A worker unloads packages from a FedEx truck in San Francisco, California, US, on Wednesday, Dec. 17, 2025.

David Paul Morris | Bloomberg | Getty Images

With the rise of automation, companies are weighing the balance between their human workers and their technological innovations.

UPS has announced layoffs north of 75,000 over the past year as the company focuses on efficiency and cuts down its partnership with Amazon amid a multiyear turnaround plan.

The company also said it closed 93 buildings in 2025 and plans to shutter at least 24 buildings in the first half of 2026.

“What’s happening is you’re seeing a cascading effect of sites being closed that are legacy conventional facilities, a lot of labor required to run those facilities, to a much more nimble, quicker, automated, consolidated facility,” Executive Vice President Nando Cesarone said on the January call.

In a statement to CNBC, a UPS spokesperson said the company is focused on making jobs easier for its employees and that the AI and robotics take on repetitive tasks that “make us more efficient in other functions.”

FedEx did not respond to requests for comment on how the company is balancing its workforce and technology. Subramaniam said on the most recent earnings call that the Network 2.0 initiative has resulted in “structural cost reductions” but the company has not publicly disclosed job cut amounts.

Teamsters, the union representing workers from many of the major packaging companies, said it will remain focused on ensuring its team members have a voice at the table when it comes to technology.

“We never want to get in the way of technology and its development, but all of that, it must support workers, and it cannot work against them ever,” spokesperson Lena Melentijevic told CNBC. “It’s the workers who are the backbone of each one of these companies and who are essential to their success, and we are here to advocate for them and hold companies accountable.”

DHL’s Tetzlaff said the company wants its automation to complement human labor instead of replacing it altogether. Regardless of how much DHL’s technology improves, Tetzlaff said the dexterous tasks of packaging and shipping remain in the hands of the employees.

“In the time where we deployed 8,000 collaborative robotics into our operation worldwide, we still hired 40,000 people,” he said.

The biggest area where DHL has deployed its robotics is in item picking, with more than 2,500 robots using trained arms to select items for packages. This past holiday season, to keep up with the Black Friday and Christmas demand, the company added 30% capacity to its robotic fleet.

“There’s an advantage for us as a company, having a great human fleet of workers that is motivated and likes the job, but complementing this with a robotic fleet that we can scale up and down and have that flexible stability to deal with change, the peaks throughout the year, be it bigger changes like Covid, be it [customer] profile changes and so on,” he said.

The path forward for investment

DHL Autonomous Forklift at work.

Source: DHL

Still, it’s unlikely there will be a near future in which warehouses are full of humanoid robots, according to supply chain expert and Accenture logistics and fulfillment lead Benjamin Reich.

Humanoid robots have been gaining intense popularity as tech companies innovate human-like machines, with Nvidia CEO Jensen Huang saying he believes the innovation is fast moving. At the January CES trade show, Google announced a partnership with Boston Dynamics, the same company working with DHL, to augment the tech company’s new robot named Atlas.

But Reich said among his clients, he’s seeing that “humans are still in the lead.”

“We are also not seeing a replacement of jobs, but a shifting that you’re more looking for skill sets on the market to serve the gap between degree of automation, operational tasks as well as organizational,” Reich told CNBC.

The automation is angled toward specific jobs, he added, with robots taking over repetitive tasks and companies instead “redirecting” their hiring toward technical roles instead of eliminating job growth altogether.

Reich said the industry is seeing rising investments into automation, with the biggest gains coming not from replacing people, but through increasing the efficiency of the supply chain and warehouse execution processes.

There are also factors in the broader industry that are impacting the workforce, according to Ronny Horvath, the transportation and logistics lead at Accenture. There’s a shortage of skilled workers who have both the manual skills and the organizational skills needed for the sector, and there’s also competition among companies for warehouse personnel based on pay, benefits, lifestyle and more.

“So automation can also help, not replacing but augmenting that gap, that void, that has been left by just not getting the workers that you have today,” Horvath said. “And we see a lot of clients, they have an automation or robotic strategy … but they still have the plans to hire human workers as well.”

Horvath added that the industry is reaping the rewards of its new technology. He’s seen companies able to adjust to deliver on high demand, increase efficiency and work toward more automated processes to keep up with warehousing.

According to an Accenture study from March, 51% of factories globally expect to have fully automated warehouses by 2040, and 70% of transportation logistics executives treat autonomous supply chains as a top investment priority.

“There’s almost no autonomous structure existing at the moment,” Horvath said. “So most or some of these clients are starting from scratch, and this will take time until these investments are done and until they also reap the benefits out of it for all those areas.”

-

Entertainment1 week ago

Entertainment1 week agoHow a factory error in China created a viral “crying horse” Lunar New Year trend

-

Tech7 days ago

Tech7 days agoNew York Is the Latest State to Consider a Data Center Pause

-

Business3 days ago

Business3 days agoAye Finance IPO Day 2: GMP Remains Zero; Apply Or Not? Check Price, GMP, Financials, Recommendations

-

Tech1 week ago

Tech1 week agoPrivate LTE/5G networks reached 6,500 deployments in 2025 | Computer Weekly

-

Tech1 week ago

Tech1 week agoNordProtect Makes ID Theft Protection a Little Easier—if You Trust That It Works

-

Business1 week ago

Business1 week agoStock market today: Here are the top gainers and losers on NSE, BSE on February 6 – check list – The Times of India

-

Fashion3 days ago

Fashion3 days agoComment: Tariffs, capacity and timing reshape sourcing decisions

-

Business1 week ago

Business1 week agoMandelson’s lobbying firm cuts all ties with disgraced peer amid Epstein fallout