Business

The green steel firms looking to revive US steel making

Chris BaraniukTechnology Reporter

Boston Metal

Boston MetalAn activity centre for babies and toddlers, an Indian restaurant, an indoor golf centre – and a mini experimental steel plant. These businesses are among those that make up a small retail and industrial estate in the city of Woburn, Massachusetts.

“People are dropping off their kids. That kind of shows you an extreme example of what the future of steel looks like,” says Adam Rauwerdink, vice president of business development at US-based green steel start-up, Boston Metal. “You can be making steel and sharing a parking lot with a daycare.”

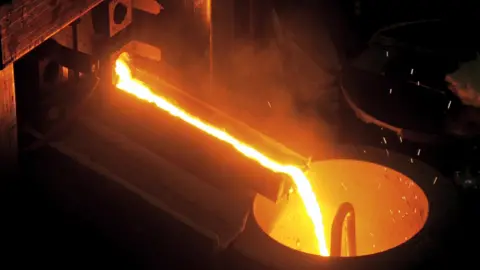

Boston Metal has come up with a way of using electricity to remove oxides and other contaminants from iron ore, which is the substance you have to mine from the Earth before you can make new steel.

The process involves distributing the ore within an electrolyte and then using electricity to heat this mixture to 1,600C. Molten iron then separates from impurities and can be tapped off.

Traditionally, extracting that all-important iron from ores requires blast furnaces that run on fossil fuels. But the iron and steel industry are responsible for 11% of global emissions – a huge amount, equivalent to all the world’s private cars and vans – and so now a race is on to find greener ways of producing these important metals.

US companies are, arguably, at the forefront. Steelmaking in the US is already greener than in many countries, thanks to the popularity of electric arc furnaces there. These furnaces use electricity, not heat from burning fossil fuels, to melt scrap steel – for example – and recycle it.

Plus, a handful of emerging start-ups such as Boston Metal say they can go one better and use electricity for the iron-making process, a crucial step in making brand new, or virgin, steel.

However, the Trump administration has taken a less than enthusiastic stance towards renewable energy and decarbonisation projects. It remains to be seen whether these new start-ups will make a big, molten splash in the steel industry any time soon.

Switching from traditional blast furnaces to electric arc furnaces can lower carbon emissions per tonne of steel produced from 2.32 tonnes of CO2 to 0.67 tonnes of CO2.

For iron-making, some plants could use green hydrogen – made using electricity from 100% renewable sources – says Simon Nicholas, lead steel analyst at the Institute for Energy Economics and Financial Analysis.

But switching iron and steel-making plants over to green hydrogen hasn’t gone as smoothly as some had expected.

In June, Cleveland-Cliffs, a major US steel producer, appeared to back away from its plans to build a $500m (£375m) hydrogen-powered steel plant in Ohio. The BBC has contacted Cleveland-Cliffs for comment.

“We’re seeing projects cancelled, proponents pulling out of projects all over the place,” says Mr Nicholas, of green hydrogen initiatives, specifically.

Bloomberg via Getty Images

Bloomberg via Getty ImagesPlus, there is a limit to how much steel-making can rely on electric arc furnaces since they currently largely rely on a supply of scrap steel.

A relatively low supply of scrap steel in China, versus demand, has slowed the rollout of electric arc furnaces there, according to some analyses.

These headaches would suggest that there is a niche for companies developing alternative ways of making iron and steel. Boston Metal is one.

“It looks a lot like how we make iron and steel today – it’s a lot easier to conceive how that would get to scale [as a result],” says Paul Kempler, an expert in electrochemistry and electrochemical engineering at the University of Oregon.

However, he notes that there are still challenges in ensuring that electrolysis systems like this don’t corrode too quickly over time. Boston Metal says it hopes to have its first demonstration-scale steel plant operational by 2028.

Electra

ElectraSeparately, the US firm Electra is taking a different approach to producing highly purified iron from ores. Unlike Boston Metal, Electra’s process runs at a relatively low temperature, around 60-100C. First, iron ore is dissolved into an acidic solution and then an electrical charge causes the iron to collect onto metal plates. This is similar to the process currently used for making sheets of copper and zinc today.

“These plates are extracted automatically out of the solution and the iron is harvested,” says Sandeep Nijhawan, co-founder and chief executive. A demonstration plant in Colorado, which could produce 500 tonnes of iron annually, is currently set to open next year.

Initially, iron produced in this manner would cost more than iron made using traditional techniques. But that “green premium” could fall away should the company be able to scale sufficiently, says Mr Nijhawan.

Bloomberg via Getty Images

Bloomberg via Getty ImagesMr Nicholas says that emerging technologies such as this are hopeful, but one challenge they face is in breaking into the market in a big way within just a few years, since the need to slash emissions and curb climate change is become more and more urgent: “We’re running short of time for addressing carbon emissions.”

Companies such as Electra and Boston Metal offer a completely different vision of the steel-making industry but they won’t get far without further investment – and a market that appreciates what they are doing.

President Donald Trump’s tariffs on steel imports to the US are supposedly designed to protect the domestic steel industry – and yet they risk raising the cost of steel substantially for US customers.

I ask whether Dr Rauwerdink, for one, is happy to see this move, or not. “We’re quite happy to see the strong focus on critical metals,” he says, arguing the tariffs are “beneficial” for Boston Metal.

Though he acknowledges that US government’s attitude towards renewable electricity, which Boston Metal says it want to prioritise as an energy source, has changed lately. And, globally, keeping the cost of renewable energy low is important for any firm hoping to electrify industries previously dominated by fossil fuels.

“The industry has growing pains there, for sure,” he says.

Business

Jamie Dimon says U.S. should impose Trump’s credit card rate cap in Vermont and Massachusetts

Jamie Dimon, CEO of JPMorgan Chase, speaks at the American Business Forum at the Kaseya Center in Miami on Nov. 6, 2025.

Chandan Khanna | AFP | Getty Images

JPMorgan Chase CEO Jamie Dimon on Wednesday advocated for a test of President Donald Trump‘s proposed 10% cap on credit card interest rates in two U.S. states: Vermont and Massachusetts.

Dimon, speaking on a panel at the World Economic Forum at Davos, Switzerland, addressed a question about Trump’s order for banks to voluntarily limit their interest rates for a year. The president had called for the lower rates to take effect Tuesday.

Several large credit card lenders contacted by CNBC on Tuesday said they had made no changes to their interest rates, but they all declined to be identified as defying Trump’s proposal.

“It would be an economic disaster,” Dimon said Wednesday. “In the worst case, you’d have a drastic reduction of the credit card business” for 80% of Americans, he said.

In earnings conference calls last week and behind the scenes, banks have pushed back against Trump’s order this month to voluntarily forgo billions of dollars in revenue.

Their main argument, that price controls will result in lenders canceling accounts for many card customers, has resonated with several Republican lawmakers, including House Speaker Mike Johnson. Most banking analysts believe that Trump would need legislation to enact a nationwide cap on card rates.

‘A great idea’

Dimon then said he had a “great idea” to help quell disagreement over the proposed card cap, suggesting that the U.S. government impose the pricing controls on Americans in just two states.

Vermont and Massachusetts are the home states of Sens. Bernie Sanders and Elizabeth Warren, respectively, both of whom support a bill capping card rates at 10% for five years. Dimon didn’t mention the lawmakers by name Wednesday.

The U.S. government “should force all the banks to do it in two states, Vermont and Massachusetts, and see what happens,” Dimon said, drawing laughter from the audience.

Dimon said “the left” and people who argue for price controls “will learn a real lesson, and the people crying the most won’t be the credit card companies,” he said.

“It’ll be the restaurants, the retailers, the travel companies, the schools, the municipalities, because people miss their water payments,” he said. “It would be something else to watch.”

The offices of Sanders and Warren did not immediately return calls for comment.

Dimon added that JPMorgan was planning on giving the Trump administration its analysis on what would happen under a national credit card rate cap.

“I think it’s wrong for the government to get involved extensively in pricing of stuff, but I got to deal with the world I got,” Dimon said.

Business

Stocks rally as Trump calms Greenland rhetoric

The FTSE 100 shrugged off a weak start to close slightly higher on Wednesday after US president Donald Trump said he would not use force to take control of Greenland, but insisted America must still have “ownership” of it.

Kathleen Brooks, research director at XTB, said Mr Trump’s speech at Davos, in Switzerland, had two key takeaways for markets.

“Firstly, Trump will not take Greenland by force and second, Trump wants the economy to run hot to send US stocks flying north,” she said.

The FTSE 100 index closed up 11.31 points, 0.1%, at 10,138.09.

The FTSE 250 ended 113.42 points higher, 0.5%, at 23,071.29, and the AIM All-Share closed up 7.45 points, 0.9%, at 808.59.

In a wide-ranging, often rambling speech at the World Economic Forum, Mr Trump said: “We probably won’t get anything unless I decide to use excessive strength and force where we would be, frankly, unstoppable, but I won’t do that.”

But he demanded “immediate” talks on Washington’s acquisition of Greenland, renewing his push to seize control of the autonomous territory from Nato ally Denmark.

“It’s the US alone that can protect this giant mass of land, this giant piece of ice, develop it and improve it,” Mr Trump told world leaders.

“That’s the reason I’m seeking immediate negotiations to once again discuss the acquisition of Greenland by the US.”

Prime Minister Sir Keir Starmer earlier told Parliament he would not give in to pressure from Mr Trump over the future of Greenland.

“I will not yield, Britain will not yield on our principles and values about the future of Greenland under threats of tariffs, and that is my clear position,” he told MPs, adding that he would host Danish counterpart Mette Frederiksen in London on Thursday.

Mr Trump has threatened to slap tariffs on Britain and other European countries for opposing his claims on Greenland.

“Greenland could still be an issue for financial markets, since Trump has said that he wants to gain control of Greenland and will start immediate negotiations to do so. However, today’s speech suggests that Nato is not under immediate threat, for now,” Ms Brooks said.

In European equities on Wednesday, markets were mixed. The CAC 40 in Paris closed up 0.1%, while the DAX 40 in Frankfurt ended 0.6% lower.

In New York, financial markets were higher at the time of the London equity market close.

The Dow Jones Industrial Average was up 0.9%, as was the S&P 500, while the Nasdaq Composite climbed 1.0%.

Bond markets were calmer after Tuesday’s sharp moves. The yield on the US 10-year Treasury was quoted at 4.27%, trimmed from 4.28% on Tuesday. The yield on the US 30-year Treasury was quoted at 4.89%, narrowed from 4.91%.

Back in London, analysts played down a surprise spike in UK inflation, calling it a “blip”.

“It was always likely that the December figures would post a rebound on account of the rise in tobacco duty rates showing up in the December data rather than November (as it did in 2024) due to the later timing of last year’s budget,” analysts at Lloyds Bank said.

“Some unwinding of the ‘early’ Black Friday discounting seen in the November data also looks to have been behind the upward move, as well as base effects associated with a sharp rise in airfares last month relative to a more subdued increase in December 2024,” the bank added.

Headline consumer prices index (CPI) inflation accelerated in December, with CPI rising by 3.4% year-on-year, up from 3.2% in November, according to data published on Wednesday by the Office for National Statistics (ONS). It was ahead of the FXStreet-cited consensus of 3.3%.

It was the first time headline inflation has risen since July, when the annual rate rose to 3.8% from 3.6% in June. Figures for October at 3.6% and November at 3.2% were lower than the consensus forecast at the time.

The ONS said alcohol, tobacco and transport made the largest upward contributions to the monthly change.

Core CPI, which excludes energy, food, alcohol and tobacco, was unchanged at 3.2%, better than the 3.3% consensus.

The CPI goods annual rate rose to 2.2% from 2.1%, while the CPI services annual rate rose to 4.5% from 4.4%, but below the 4.6% consensus.

RBC Capital Markets expects the December “blip” to fall away sharply in the first half of 2026.

“Not only therefore did the December outturn leave services and headline CPI inflation broadly in line with the BoE’s (Bank of England’s) projections from November but also the main upward contributions to both headline and CPI were concentrated in non-core or more volatile categories,” the broker said.

Deutsche Bank expects inflation will take a big step down in January, pushing to near 3% year-on-year.

And by spring, the bank expects the BoE’s 2% inflation target “to be in sight”.

The pound was quoted lower at 1.3437 US dollars at the time of the London equities close on Wednesday, compared to 1.3462 dollars on Tuesday.

The euro stood at 1.1707 dollars, lower against 1.1733 dollars. Against the yen, the dollar was trading at 158.18 yen, higher from 157.95 yen.

On the FTSE 100, trading statements boosted Burberry but weighed on Experian.

Luxury goods manufacturer Burberry rose 5.0% after announcing an increase in comparable store sales over the festive period, while it expects its annual adjusted operating profit to be in line with analyst consensus estimates.

Comparable sales by region in the third quarter of financial year 2026, which runs until March 28, were up 6% in Greater China and 5% higher in Asia Pacific. They were up 2% in the Americas. Further, comparable sales were flat in Europe, Middle East, India & Africa due to declines in tourist spend.

Miners were in demand with Rio Tinto, up 5.2% after a well-received fourth quarter production update, and Glencore, which Rio is trying to buy, up 3.7%.

Bank of America said it believes “GlenTinto” – should a deal be sealed – offers “compelling value”.

Rio has until February to firm up an approach for Glencore.

Heading south, insurer Admiral, down 4.2%, after Goldman Sachs downgraded to “sell” from “buy”, while Experian slipped 4.9% despite reporting in-line trading.

On the FTSE 250, Currys shares sparked 7.7% higher as the electricals retailer rose profit guidance, while Premier Foods climbed 7.1% after it signalled top-end full-year profits.

But pub chain JD Wetherspoon failed to cheer investors, with shares down 8.1%, as it said higher costs were offsetting growth in sales.

Brent oil traded lower at 64.82 dollars a barrel on Wednesday, down from 64.89 dollars late on Tuesday.

Gold was quoted at 4,833.66 dollars an ounce on Wednesday, after hitting another record high, up from 4,742.56 dollars on Tuesday.

The biggest risers on the FTSE 100 were Rio Tinto, up 327.00 pence at 6,641.00p, Burberry, up 61.00p at 1,280.00p, Bunzl, up 97.00p at 2,086.00p, Anglo American, up 158.00p at 3,401.00p, and JD Sports Fashion, up 3.78p at 82.06p.

The biggest fallers on the FTSE 100 were Experian, down 157.00p at 3,070.00p, Admiral Group, down 128.00p at 2,948.00p, London Stock Exchange, down 198.00p at 8,782.00p, Rolls Royce, down 26.00p at 1,255.00p and Sage Group, down 16.50p at 1,025.00p.

Thursday’s global economic calendar has public sector net borrowing figures, plus GDP data, initial jobless claims and personal consumption expenditures data.

Thursday’s UK corporate calendar has trading statements from discount retail chain B&M European Value Retail and trading platform AJ Bell.

Contributed by Alliance News

Business

Local audit push: CAG flags capacity gaps, calls for stronger PAIs and tech-led audits – The Times of India

The Comptroller and Auditor General of India has called for strengthening the institutional framework, professional capacity building and audit practices of primary auditing institutions (PAIs) responsible for local governments, highlighting the need to improve audit quality and transparency at the grassroots level, PTI reported.The call came at the conclusion of a three-day national workshop for Directorates of Local Fund Audit (DLFAs) and state audit departments, organised by CIARD–NIRDPR in collaboration with iCAL, the CAG office said in a statement on Wednesday.Speaking at the valediction function, CAG Sanjay Murthy said the challenges and best practices highlighted by different states during the workshop would be taken up at the forthcoming All-State Secretaries’ Workshop for “appropriate follow-up and improvement of the system”.The workshop focused on strengthening PAIs, which play a key role in auditing local governments. Workshop Director U Hemantha Kumar said deliberations covered issues such as challenges in local fund audits, assessment of PAI maturity, the CAG’s Technical Guidance and Support (TGS) framework, and experience-sharing on audit planning, reporting and engagement with local bodies.Directors of Local Fund Audit from various states participated in five thematic group discussions, which examined PAI maturity levels, virtual audit systems, remote audits of gram panchayats, standardisation of inspection reports and audit planning, and ways to strengthen the TGS framework.According to the CAG statement, group presentations stressed the need for simplified and standardised audit frameworks, wider adoption of technology-enabled and remote audit systems, and stronger follow-up and enforcement mechanisms. Participants also underlined the importance of focused capacity building of DLFAs to enhance audit coverage, improve audit quality and increase transparency in local governance.The workshop concluded with a consensus that upgrading institutional capacity and modernising audit practices are essential to ensure effective oversight of local bodies and better utilisation of public funds.

-

Tech1 week ago

Tech1 week agoNew Proposed Legislation Would Let Self-Driving Cars Operate in New York State

-

Entertainment1 week ago

Entertainment1 week agoX (formerly Twitter) recovers after brief global outage affects thousands

-

Politics5 days ago

Politics5 days agoSaudi King Salman leaves hospital after medical tests

-

Sports7 days ago

Sports7 days agoPak-Australia T20 series tickets sale to begin tomorrow – SUCH TV

-

Fashion5 days ago

Fashion5 days agoBangladesh, Nepal agree to fast-track proposed PTA

-

Business5 days ago

Business5 days agoTrump’s proposed ban on buying single-family homes introduces uncertainty for family offices

-

Tech7 days ago

Tech7 days agoTwo Thinking Machines Lab Cofounders Are Leaving to Rejoin OpenAI

-

Tech6 days ago

Tech6 days agoMeta’s Layoffs Leave Supernatural Fitness Users in Mourning