Business

A ‘war room’ mentality: How auto giants are battling the Nexperia chip crunch

A Honda sedan moves down the assembly line on Jan. 28, 2025 at the automaker’s assembly plant in Marysville, Ohio.

Michael Wayland / CNBC

Global automakers are once again bracing for production disruptions due to a potential shortage of automotive semiconductor chips, this time sparked by the Dutch government amid geopolitical tensions between the U.S. and China.

Honda Motor became the first known automaker this week to reduce production due to the problem that involves chips from Netherlands supplier Nexperia, which is owned by Chinese company Wingtech Technology Co.

The industry was hopeful that a meeting this week between President Donald Trump and Chinese leader Xi Jinping in Asia would provide some relief, but no resolution on the chips issue has been announced.

Volkswagen on Thursday reportedly said it has until at least next week before its supplies impact production, while other major automakers have said they are monitoring the situation around the clock, attempting to mitigate disruptions.

“The chip situation from Nexperia, we have a cross-functional ‘war room’ in the building where I’m sitting that has this as [a] primary job,” Stellantis CEO Antonio Filosa told investors during a quarterly call Thursday. “And every day we are pushing actions and projects to extend our period. There is a day-by-day management of what is an industrywide global issue.”

U.S. President Donald Trump and Chinese President Xi Jinping shake hands as they depart following a bilateral meeting at Gimhae Air Base on October 30, 2025 in Busan, South Korea.

Andrew Harnik | Getty Images

Such “war rooms” have become a regular practice in the automotive industry amid supply chain disruptions, which have become more common since the Covid pandemic rattled production and deliveries of many parts, including chips, starting in 2020.

Several automotive industry insiders confirmed to CNBC that war rooms have been established in their companies, as they look into alternative purchasing methods. They included working with major suppliers in an attempt to find alternative sources as well as buying on the open market.

“Suppliers across the motor vehicle industry are working to understand the potential effects on production and supply continuity,” MEMA, the largest vehicle supplier association in the U.S., said in an emailed statement. “Chips and diodes are foundational to automotive components and systems, from infotainment systems to door handles, to steering and braking. Even the absence of a single diode or chip can disrupt the manufacture of vehicles.”

Nexperia

The situation involving Nexperia began late last month, when the Dutch government took control of the company, in what was seen as a highly unusual move, reportedly after the U.S. raised security concerns.

In making the decision, the Dutch government cited fears that tech from the company — which specializes in the high-volume production of chips used in automotive, consumer electronics and other industries — “would become unavailable in an emergency.”

China responded by blocking exports of the firm’s finished products, sparking alarm in Europe’s auto industry.

German automakers are especially sensitive to Nexperia-related disruptions because they rely heavily on large, domestic suppliers, known as “Tier 1s,” and local production facilities and companies, such as Nexperia, despite much of its manufacturing moving to China.

The European Automobile Manufacturers’ Association said this week that carmakers were close to closing production lines because of the chip shortage, which comes four years after a shortage of such parts amid the coronavirus pandemic.

A close-up view of the Nexperia plant sign in Newport, Wales on April 1, 2022.

Matthew Horwood | Getty Images News | Getty Images

“This means assembly line stoppages might only be days away. We urge all involved to redouble their efforts to find a diplomatic way out of this critical situation,” ACEA Director General Sigrid de Vries said in a statement.

The chips affected are legacy semiconductors used in basic vehicle functions such as windshield wipers and window controls — parts that lack sufficient alternative sources, according to S&P Global Mobility.

A Nexperia spokesman referred to a previous statement from the company, which summarized the ongoing situation and said it is seeking an exemption from the export restrictions and working to mitigate the impacts of the decision.

A Wingtech spokesperson on Thursday condemned the Dutch government’s actions, saying the company “will robustly defend its rights and use every legal avenue to do so.”

“Only by restoring full control and ownership rights to the company’s rightful shareholders and management, and by ceasing political interference in corporate governance, can the Dutch government begin to repair the damage to its reputation, de-escalate international tension, and safeguard its own and European economic security,” the spokesperson said via an emailed statement.

Fluid situation

Honda’s production cuts impacts include all of its main North American plants, including large vehicle assembly and supporting facilities across the U.S., Canada and Mexico.

“We are currently managing an industrywide semiconductor supply chain issue, making strategic adjustments to production as necessary to carefully manage the available supply of parts and meet the needs of our customers,” Honda said Thursday in an emailed statement, calling it a “fluid” situation.

The impacts are expected to continue to spread to other automakers if a resolution is not found.

Ford Motor CEO Jim Farley last week said the chip problem was at the forefront of conversations when he made a trip to Washington, D.C, earlier this month. He called it a “political issue,” saying the company is working with the U.S. and China administrations to resolve it.

“It’s an industrywide issue. A quick breakthrough is really necessary to avoid fourth-quarter production losses for the entire industry,” said Farley, adding that automakers have gotten “really good” at maximizing component purchases such as chips following the crisis in 2021.

General Motors CEO Mary Barra made similar comments last week, calling it an “industry issue” that will hopefully be resolved soon.

“While this has the potential to impact production, we have teams working around the clock with our supply chain partners to minimize possible disruptions. The situation is very fluid and we will provide updates throughout the quarter as appropriate,” she said during the company’s quarterly earnings call.

Other automotive executives from Volvo, Mercedes-Benz and more have also shared similar thoughts with investors and the media.

“This is a politically induced situation … which means that the solution to this, or the resolution to this, resides in the political space, primarily between the United States and China, in this case, with Europe kind of caught in the middle,” Mercedes-Benz CEO Ola Källenius said Wednesday during an earnings call.

Business

Trade deal done, says Trump; PM Modi thanks him for cutting tariff to 18% – The Times of India

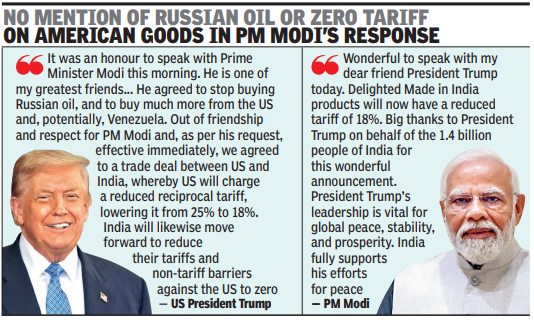

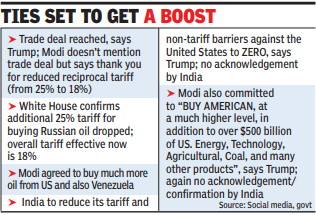

NEW DELHI/ WASHINGTON: After months of bruising trade tensions, India and the US on Monday announced a bilateral trade deal that will see Washington slash additional tariffs on Indian imports to 18%, from the current 50%, making it more competitive for textiles, leather and seafood exporters.While PM Narendra Modi, in a post on X, which followed US President Donald Trump’s announcement on Truth Social, said he had a wonderful conversation with “dear friend” Trump and thanked him on behalf of 1.4 billion people for the reduced tariff of 18% on Indian goods, he did not mention the trade deal at all in his post on X that followed Trump’s “wonderful” announcement.

PM Modi and Trump

Modi also did not comment on Trump’s claim that in their conversation the PM had agreed to stop buying Russian oil and purchase much more energy from the US, and potentially Venezuela. Trump had said Modi had agreed to stop buying Russian oil and to buy much more from the US — $500 billion of energy, technology and farm products — a step that the President claimed would help end the war in Ukraine.According to the American President, Modi also agreed to bring down tariff and non-tariff barriers against the US to zero. A US embassy spokesperson confirmed that the final tariff now on India is 18%, down from the earlier 50%. This is a better deal for India than countries such Vietnam, Bangladesh, Indonesia, South Korea and China, which face higher tariffs. The Trump-Modi conversation coincided with the visit of EAM S Jaishankar to US for a critical minerals ministerial that will be chaired by Secretary of State Marco Rubio this week.The announcement came six days after India and the EU announced the completion of talks for a comprehensive trade agreement.Trump leadership vitalfor global peace: ModiThe deal had drawn sharp comments from some members of the Trump administration, including attacks on the EU.In his X post, PM said, “When two large economies and the world’s largest democracies work together, it benefits our people and unlocks immense opportunities for mutually beneficial cooperation”. He added that Trump’s leadership was vital for global peace, stability, and prosperity. India fully supports his efforts for peace. Modi said he was looking forward to working closely with Trump to take the partnership to unprecedented heights.Apart from reciprocal tariff, Trump had announced an additional 25% tariff on India for its purchase of Russian oil.Trump said the US had agreed to the trade deal with India out of friendship and respect for Modi, and at the latter’s request. “Our amazing relationship with India will be even stronger going forward. PM Modi and I are two people that GET THINGS DONE, something that cannot be said for mos,” he added.Trump in his social media post also said that it was an honour to speak with Modi whom he described as “one of my greatest friends and, a Powerful and Respected Leader of his Country”.

Ties set to get boost

While the US had acknowledged in past few months that India had cut down its Russian purchase, it had not eliminated the additional tariff.Trump also said, “We spoke about many things, including Trade, and ending the War with Russia and Ukraine. He agreed to stop buying Russian Oil, and to buy much more from the US and, potentially, Venezuela. This will help END THE WAR in Ukraine, which is taking place right now, with thousands of people dying each and every week!”Following the announcement last week of the successful conclusion of FTA negotiations with EU, India had suggested that India and US might be close to finalising the trade agreement they have been discussing since Feb last year.Trump’s disclosure of the trade deal was preceded by two India-related posts a few hours before, one of which featured him and Modi on a magazine cover with the caption “The Mover and the Shaker”. Another post featured New Delhi’s India Gate, which Trump called “India’s beautiful Triumphal Arch” and said, “Ours will be the greatest of them all!” — referring to a similar monument he wants to build in Washington DC.

Business

New York AG issues warning around prediction markets ahead of Super Bowl

New York Attorney General Letitia James speaks to the media, after she attended a hearing and pleaded not guilty to charges that she defrauded her mortgage lender, outside the U.S. District Court for the Eastern District of Virginia, in Norfolk, Virginia, U.S., Oct. 24, 2025.

Jonathan Ernst | Reuters

Days before Super Bowl 60, New York Attorney General Letitia James has a message for consumers: Be careful about placing trades on prediction markets.

“New Yorkers need to know the significant risks with unregulated prediction markets,” James said in a statement Monday. “It’s crystal clear: so-called prediction markets do not have the same consumer protections as regulated platforms. I urge all New Yorkers to be cautious of these platforms to protect their money.”

Prediction platforms like Kalshi and Polymarket are expected to generate billions of dollars in trading volume around the Super Bowl.

Consumers can make trades on game events — similar to online sportsbooks like DraftKings or FanDuel — as well as on predetermined outcomes, such as which companies will advertise during the Super Bowl, an issue CNBC Sport reported on last week.

James said the platforms’ products are bets “masquerading” as event contracts.

She warned there are concerns about the nascent prediction market industry, including “upholding prohibitions against insider betting and requiring regulatory review to ensure the financial stability and integrity of gambling operators.”

“Prediction markets may appear as modern, high-tech platforms for speculation or ‘forecasting,’ but in practice, many operate as unregulated gambling without the basic protections New York consumers both deserve and expect from properly licensed operators,” James said in the statement.

Prediction market contracts trade somewhat similarly to all-or-nothing options, with contracts priced between $0 and $1. The contracts trade up or down depending on the action.

In addition to contracts on Super Bowl commercials, both Polymarket and Kalshi are offering other trades related to the game, including on matters like “What songs will be played at the halftime show?,” “Who will attend the big game?,” and more traditional sportsbook “bets” such as “Seattle vs. New England: Most Rushing Yards,” as CNBC reported last week.

There are laws that prohibit insider trading on prediction markets, just as on traditional financial markets. But industry experts say they’re skeptical that the Commodity Futures Trading Commission, recently gutted as part of widespread government cuts, has the will or the means to police those problems.

Last week, CFTC Chairman Michael Selig said he had directed agency staff to withdraw a proposed rule that would have banned prediction trades on sports and politics. He said new rules would be coming.

Disclosure: CNBC has a commercial relationship with Kalshi.

Business

Gold and silver prices fall but FTSE 100 hits record high

Precious metal prices hit record highs in January as investors parked their money in “safe havens”.

Source link

-

Sports6 days ago

Sports6 days agoPSL 11: Local players’ category renewals unveiled ahead of auction

-

Entertainment6 days ago

Entertainment6 days agoClaire Danes reveals how she reacted to pregnancy at 44

-

Business7 days ago

Business7 days agoBanking services disrupted as bank employees go on nationwide strike demanding five-day work week

-

Fashion1 week ago

Fashion1 week agoSpain’s apparel imports up 7.10% in Jan-Oct as sourcing realigns

-

Sports6 days ago

Sports6 days agoCollege football’s top 100 games of the 2025 season

-

Sports6 days ago

Sports6 days agoTammy Abraham joins Aston Villa 1 day after Besiktas transfer

-

Entertainment6 days ago

Entertainment6 days agoK-Pop star Rosé to appear in special podcast before Grammy’s

-

Politics6 days ago

Politics6 days agoTrump vows to ‘de-escalate’ after Minneapolis shootings