Business

The green steel firms looking to revive US steel making

Chris BaraniukTechnology Reporter

Boston Metal

Boston MetalAn activity centre for babies and toddlers, an Indian restaurant, an indoor golf centre – and a mini experimental steel plant. These businesses are among those that make up a small retail and industrial estate in the city of Woburn, Massachusetts.

“People are dropping off their kids. That kind of shows you an extreme example of what the future of steel looks like,” says Adam Rauwerdink, vice president of business development at US-based green steel start-up, Boston Metal. “You can be making steel and sharing a parking lot with a daycare.”

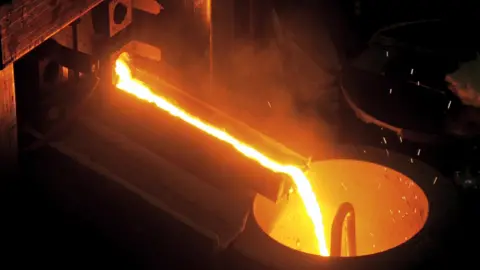

Boston Metal has come up with a way of using electricity to remove oxides and other contaminants from iron ore, which is the substance you have to mine from the Earth before you can make new steel.

The process involves distributing the ore within an electrolyte and then using electricity to heat this mixture to 1,600C. Molten iron then separates from impurities and can be tapped off.

Traditionally, extracting that all-important iron from ores requires blast furnaces that run on fossil fuels. But the iron and steel industry are responsible for 11% of global emissions – a huge amount, equivalent to all the world’s private cars and vans – and so now a race is on to find greener ways of producing these important metals.

US companies are, arguably, at the forefront. Steelmaking in the US is already greener than in many countries, thanks to the popularity of electric arc furnaces there. These furnaces use electricity, not heat from burning fossil fuels, to melt scrap steel – for example – and recycle it.

Plus, a handful of emerging start-ups such as Boston Metal say they can go one better and use electricity for the iron-making process, a crucial step in making brand new, or virgin, steel.

However, the Trump administration has taken a less than enthusiastic stance towards renewable energy and decarbonisation projects. It remains to be seen whether these new start-ups will make a big, molten splash in the steel industry any time soon.

Switching from traditional blast furnaces to electric arc furnaces can lower carbon emissions per tonne of steel produced from 2.32 tonnes of CO2 to 0.67 tonnes of CO2.

For iron-making, some plants could use green hydrogen – made using electricity from 100% renewable sources – says Simon Nicholas, lead steel analyst at the Institute for Energy Economics and Financial Analysis.

But switching iron and steel-making plants over to green hydrogen hasn’t gone as smoothly as some had expected.

In June, Cleveland-Cliffs, a major US steel producer, appeared to back away from its plans to build a $500m (£375m) hydrogen-powered steel plant in Ohio. The BBC has contacted Cleveland-Cliffs for comment.

“We’re seeing projects cancelled, proponents pulling out of projects all over the place,” says Mr Nicholas, of green hydrogen initiatives, specifically.

Bloomberg via Getty Images

Bloomberg via Getty ImagesPlus, there is a limit to how much steel-making can rely on electric arc furnaces since they currently largely rely on a supply of scrap steel.

A relatively low supply of scrap steel in China, versus demand, has slowed the rollout of electric arc furnaces there, according to some analyses.

These headaches would suggest that there is a niche for companies developing alternative ways of making iron and steel. Boston Metal is one.

“It looks a lot like how we make iron and steel today – it’s a lot easier to conceive how that would get to scale [as a result],” says Paul Kempler, an expert in electrochemistry and electrochemical engineering at the University of Oregon.

However, he notes that there are still challenges in ensuring that electrolysis systems like this don’t corrode too quickly over time. Boston Metal says it hopes to have its first demonstration-scale steel plant operational by 2028.

Electra

ElectraSeparately, the US firm Electra is taking a different approach to producing highly purified iron from ores. Unlike Boston Metal, Electra’s process runs at a relatively low temperature, around 60-100C. First, iron ore is dissolved into an acidic solution and then an electrical charge causes the iron to collect onto metal plates. This is similar to the process currently used for making sheets of copper and zinc today.

“These plates are extracted automatically out of the solution and the iron is harvested,” says Sandeep Nijhawan, co-founder and chief executive. A demonstration plant in Colorado, which could produce 500 tonnes of iron annually, is currently set to open next year.

Initially, iron produced in this manner would cost more than iron made using traditional techniques. But that “green premium” could fall away should the company be able to scale sufficiently, says Mr Nijhawan.

Bloomberg via Getty Images

Bloomberg via Getty ImagesMr Nicholas says that emerging technologies such as this are hopeful, but one challenge they face is in breaking into the market in a big way within just a few years, since the need to slash emissions and curb climate change is become more and more urgent: “We’re running short of time for addressing carbon emissions.”

Companies such as Electra and Boston Metal offer a completely different vision of the steel-making industry but they won’t get far without further investment – and a market that appreciates what they are doing.

President Donald Trump’s tariffs on steel imports to the US are supposedly designed to protect the domestic steel industry – and yet they risk raising the cost of steel substantially for US customers.

I ask whether Dr Rauwerdink, for one, is happy to see this move, or not. “We’re quite happy to see the strong focus on critical metals,” he says, arguing the tariffs are “beneficial” for Boston Metal.

Though he acknowledges that US government’s attitude towards renewable electricity, which Boston Metal says it want to prioritise as an energy source, has changed lately. And, globally, keeping the cost of renewable energy low is important for any firm hoping to electrify industries previously dominated by fossil fuels.

“The industry has growing pains there, for sure,” he says.

Business

Women’s Day 2026: Female Investors Cut FD Allocation From 45% To 20%, Boost Equity Funds

Last Updated:

On International Women’s Day 2026, Equirus Wealth reports Indian women investors’ shift from fixed deposits and gold to equity mutual funds.

Women investors are steadily reshaping India’s financial landscape, with rising participation in stocks, mutual funds, and digital investing platforms.

On International Women’s Day 2026, a key trend of behavior change among female investors has emerged over the past five years, particularly in their investment choices across various financial products. Women are now more confident while investing in high risk but rewarding equity market, as the portfolio allocation in equity mutual funds surged from 10 per cent to 32 per cent, while down from 40 per cent to 20 per cent in Fixed Deposits (FDs).

The five-year study on women investors and relationship managers was conducted by Equirus Wealth Limited, and was published in a report titled “Expanding Horizons: Changing Wealth Management Behaviours of Indian Women – Qualitative Analysis of Investor Evolution Across Age and Affluence.”

The study reveals that women investors are increasingly moving away from episodic product purchases such as fixed deposits, gold and property towards diversified, allocation-driven portfolios anchored around long-term financial goals.

This reflects the major behavioural change from ‘safety-first’ investing to allocation-driven portfolio strategies.

Female Investors Adopting AI Cautiously

According to the report ,Artificial Intelligence may dominate global investment conversations, but Indian women investors are adopting it cautiously. They are using AI primarily as research and learning tool rather than for autonomous investment decisions.

Not Panicking During Corrections

Another interesting thing being revealed by the study is that 70-90% of investors hold or review their investments during market corrections rather than exiting in panic, showing maturity during market cycles.

At the same time, around 55% selectively add capital during market dips, reflecting growing conviction and a longer-term approach to investing.

Rise of “bucket investing”

Investors are increasingly dividing portfolios into buckets like safety, growth, liquidity and legacy instead of buying random financial products.

Risk is no longer seen only as loss of capital.

Investors now also consider inflation, goal failure, and portfolio drawdowns as risks.

75–90% are discussing intergenerational wealth transfer and financial discipline for the next generation.

Follow News18 on Google. Join the fun, play games on News18. Stay updated with all the latest business news, including market trends, stock updates, tax, IPO, banking finance, real estate, savings and investments. To Get in-depth analysis, expert opinions, and real-time updates. Also Download the News18 App to stay updated.

March 08, 2026, 14:14 IST

Read More

Business

Gold On Sale In Dubai? Here’s Why Prices Have Dropped By $30 Per Ounce

Last Updated:

Gold is sold at a discount in Dubai due to Middle East conflict disrupting flights. Traders offer up to $30 per ounce less than London prices.

Dubai Gold Selling Cheaper As Iran War Grounds Flights

Gold is being sold at a discount in Dubai as the widening conflict in the Middle East disrupts flights and hampers the movement of bullion from one of the world’s key trading hubs.

According to a Bloomberg report, traders in Dubai are offering discounts of up to $30 per ounce compared to the global benchmark price in London. The unusual price cut comes as shipments remain stranded due to flight disruptions triggered by the escalating conflict involving Iran and Israel.

Dubai is a key global centre for refining and exporting gold to markets across Asia, including India. However, partial airspace restrictions and heightened security risks have slowed the movement of bullion out of the region.

Why Gold Is Being Sold Cheaper

Gold is typically transported in the cargo holds of passenger aircraft. With several flights from the UAE restricted amid regional tensions, traders are struggling to move bullion to international markets.

At the same time, insurance and freight costs have surged, making shipments more expensive and uncertain. Many buyers have therefore stepped back from placing new orders, unwilling to bear high logistics costs without assurance of timely delivery.

To avoid paying prolonged storage and financing costs while shipments remain stuck, some traders are offering gold at discounted prices.

Although transporting bullion by road to airports in neighbouring countries such as Saudi Arabia or Oman is theoretically possible, logistics firms are reluctant due to the risks and complications of moving high-value cargo across land borders during a conflict.

What It Means For India

India, one of the largest buyers of gold shipped from Dubai, could face short-term supply disruptions if the situation continues.

Renisha Chainani, head of research at Augmont Enterprises Ltd., said several cargo shipments have already been delayed, creating temporary tightness in the availability of physical bullion in India.

However, industry experts as reported by Bloomberg say the immediate impact may remain limited as domestic inventories are currently comfortable after heavy imports earlier this year.

Chirag Sheth, principal consultant for South Asia at Metals Focus, said Bloomberg that India has ample stocks for now, but warned that prolonged disruptions could eventually affect supply if the conflict continues for several months.

Meanwhile, global gold prices have surged this year amid geopolitical uncertainty, with spot gold recently trading above $5,000 per ounce.

Follow News18 on Google. Join the fun, play games on News18. Stay updated with all the latest business news, including market trends, stock updates, tax, IPO, banking finance, real estate, savings and investments. To Get in-depth analysis, expert opinions, and real-time updates. Also Download the News18 App to stay updated.

March 08, 2026, 10:03 IST

Read More

Business

70% of adults without a licence say learning to drive is unaffordable

Some seven in 10 British adults without a full driving licence say learning to drive is currently unaffordable, according to a survey.

The figure is even higher among younger people, with 76% of 18 to 29-year-olds without a licence saying driving lessons are financially out of reach, the poll for car insurer Prima found.

Overall, 38% said the cost of driving lessons was the biggest deterrent to learning to drive.

Some 32% were put off by the price of buying a car and 15% said the cost of car insurance was the main barrier to learning to drive.

Almost half (45%) said they would consider learning to drive if it became significantly cheaper.

Nick Ielpo, UK country manager at Prima, said: “For a growing number of people, driving is no longer a symbol of freedom – it’s a financial stretch too far.

“Between lessons, buying a car and insuring it, the upfront and ongoing costs are pricing many people out before they even start.”

Find Out Now surveyed 1,134 adults who do not hold a full driving licence between January 21 and 23.

-

Sports1 week ago

Sports1 week agoLPGA legend shares her feelings about US women’s Olympic wins: ‘Gets me really emotional’

-

Entertainment1 week ago

Entertainment1 week agoPakistan’s semi-final qualification scenario after England defeat New Zealand

-

Fashion1 week ago

Fashion1 week agoSouth Korea’s Misto Holdings completes planned leadership transition

-

Entertainment1 week ago

Entertainment1 week agoBobby J. Brown, “The Wire” and “Law & Order: SUV” actor, dies of smoke inhalation after reported fire

-

Business1 week ago

Business1 week agoGreggs to reveal trading amid pressure from cost of living and weight loss drugs

-

Business1 week ago

Business1 week agoCNBC To Merge TV And Digital News Operations, Nearly A Dozen Jobs To Be Cut: Report

-

Entertainment1 week ago

Entertainment1 week agoWhat’s new in Pokémon? Every game, update, surprise from 30th anniversary event

-

Politics1 week ago

Politics1 week agoIran launches retaliation against Israel, launches ballistic missiles