Business

Will boats be a breakthrough for 3D printing tech?

Matthew KenyonTechnology Reporter, Delft, Netherlands

The final test was a blunt one. Maarten Logtenberg wielded a sledgehammer, which simply bounced off the sample, barely leaving a scratch.

After two years of experimentation, the material was finally right: a particular mix of thermoplastics and fibreglass that is strong, has no need of extra coating to protect it from sunlight, and is resistant to fouling and marine growth.

The perfect base, says Mr Logtenberg, from which to 3D print a boat.

Boats need to withstand the unforgiving nature of the marine environment. It’s one of the reasons why boatbuilding is a notoriously labour-intensive business.

But after months of tweaking the chemistry, it took just four days for the first hull to roll off the printer at the new factory that Mr Logtenberg and his colleagues run.

“We’re automating almost 90% of the boat-building process, and in superfast time,” he says.

“Normally it takes weeks to build a hull. We print one now every week.”

It’s the kind of story that 3D printing has long promised. A quick, labour-saving production process that drastically reduces costs.

Those promises haven’t always been fulfilled – but Mr Logtenberg is convinced that the maritime sector is one where 3D printing, also known as additive manufacturing, can play a transformational role.

Mr Logtenberg is the co-founder of CEAD, a company that designs and builds large-format 3D printers at its base in the Dutch town of Delft.

Until now, its business has been to provide the printers for others to use, but with boatbuilding CEAD decided to get involved in production as well.

“3D printed boats still need to be accepted by the market,” says Mr Logtenberg.

“People are not going to invest and then just hope that the market will develop. They would rather buy in capacity first. [So] instead of just building machines, we’re going to do it ourselves.”

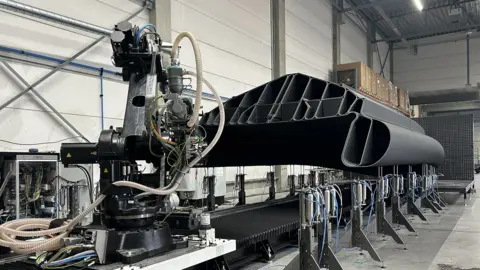

CEAD

CEADTraditional fibreglass boat building requires a mould and considerable manual work to make sure the vessel is of the required strength.

In additive manufacturing, the work has already been done at the design stage, in creating the software and the printer itself (which is labour intensive).

3D printers work by building up tiny layers of the basic material, to a predetermined digital design.

Each layer then bonds to the previous one to allow the creation of a single, seamless object.

In the production phase, as long as there is a supply of the base material, there is little or no need for human intervention.

The design can also be adjusted without the need for major changes in the build process.

Much 3D printing operates on a relatively small scale – dentistry is one area where it has made a major impact. To create a boat capable of operating in real world conditions is a different challenge.

CEAD’s largest 3D printer is nearly 40m (131ft) long, and has been used by a customer in Abu Dhabi to print an electric ferry.

And in the 12 months since they have been operating the Marine Application Centre in Delft, they have already built a prototype 12m fast boat, similar to a RIB, for the Dutch Navy.

“Normally when the Navy buys a boat, it takes them years before they receive it and they pay quite some money,” says Mr Logtenberg.

“We did it in six weeks and for a very limited budget. And we can learn from it and build another one in six weeks and even recycle the first one.”

Another fast growth area is the use of unmanned vessels – nautical drones. CEAD recently took part in a test with Nato Special Forces in which drones were built on site in a matter of hours, with designs changing according to operational requirements.

The ability to relocate production makes 3D printing incredibly flexible, according to Mr Logtenberg.

Even a substantial printer can be carried in a shipping container and taken much closer to the end user.

“It doesn’t matter whether it’s a 6m small work boat or a 12m military boat. The machine just takes it all as long as we have the design.

“The only transport we need to do is the base material, which comes in big bags and it’s very transport efficient, compared to a boat.”

Matthew Kenyon

Matthew Kenyon Raw Idea

Raw IdeaNot far from CEAD, in the port city of Rotterdam, a company called Raw Idea and their ‘Tanaruz’ brand are looking at making a similar impact in the leisure market, especially rentals.

“Consumers are hesitant [because of the novelty], but the rental market is really keen,” says Joyce Pont, Raw Idea’s managing director.

“It’s marketing, you can go to the socials and say, ‘we’ve got a 3D printed boat’, and everybody wants to look at and touch that boat.”

Another selling point is that Raw Idea uses a mix of glass fibre and recycled consumer plastics (fizzy drinks bottles and so on).

That’s one reason why the price is currently comparable to a traditionally-built boat, because recycled material costs more to buy.

But Ms Pont says scale and flexibility will bring costs down significantly.

“I’m convinced that in five years from now, 3D printed boats will take over the market for the fast-driving boat, like work boats, like speed boats,” she tells me.

The marine industry is intensely regulated but the certification authorities are having to keep pace with innovation.

Both RAW Idea and CEAD are engaging with European regulators almost in real time, as they use new materials and new ideas to produce vessels that cannot be compared to what has come before.

3D printing has often been hailed as a revolutionary technology but hasn’t always delivered on those hopes.

Mr Logtenberg says that’s because the technique is used in multiple different contexts.

“It’s all being seen as one thing, but you have metal printing, you have polymer or large-scale printing, all these different applications.

“There are many applications that didn’t succeed because it was not competitive enough, but there are a few where it actually happened and is being used.”

Additive manufacturing is being used more frequently in the shipping industry, but in technical niches, rather than entire hulls.

How far could 3D printing go in the maritime world? We are a long way from entire ships being printed in one go.

Joyce Pont is sceptical whether that moment will arrive in the foreseeable future – she sees the building of superyachts and other such vessels as a ‘craft’ which will resist automation.

But Mr Logtenberg is more optimistic.

“Building a 12-meter boat, I never expected that a year ago,” he says.

“Traditional shipbuilding is done in modules. It’s going to take maybe a decade or two before we are going to completely print [a ship’s hull], because there will be more need of material research.

“But thermal plastics are being developed and improved all the time. Of course, the machines, everything needs to be scaled up, but why not?”

Business

Peel Hunt cheers ‘positive steps’ in Budget to boost London market and investing

UK investment bank Peel Hunt has given some support to under-pressure Chancellor Rachel Reeves over last week’s Budget as it said efforts to boost the London market and invest in UK companies were “positive steps”.

Peel Hunt welcomed moves announced in the Budget, such as the stamp duty exemption for shares bought in newly listed firms on the London market and changes to Isa investing.

It comes as Ms Reeves has been forced to defend herself against claims she misled voters by talking up the scale of the fiscal challenge in the run-up to last week’s Budget, in which she announced £26 billion worth of tax rises.

Peel Hunt said: “Following a prolonged period of pre-Budget speculation, businesses and investors now have greater clarity from which they can start to plan.

“The key measures were generally well received by markets, particularly the creation of additional headroom against the Chancellor’s fiscal rules.

“Initiatives such as a stamp duty holiday on initial public offerings (IPOs) and adjustments to the Isa framework are intended to support UK capital markets and encourage investment in British companies.

“These developments, alongside the Entrepreneurship in the UK paper published simultaneously, represent positive steps toward enhancing the UK’s attractiveness for growth businesses and long-term investors.”

Ms Reeves last week announced a three-year stamp duty holiday on shares bought in new UK flotations as part of a raft of measures to boost investment in UK shares.

She also unveiled a change to the individual savings account (Isa) limit that lowers the cash element to £12,000 with the remaining £8,000 now redirected into stocks and shares.

But the Chancellor also revealed an unexpected increase in dividend tax, rising by 2% for basic and higher rate taxpayers next year, which experts have warned “undermines the drive to increase investing in Britain”.

Peel Hunt said the London IPO market had begun to revive in the autumn, although listings activity remained low during its first half to the end of September.

Firms that have listed in London over recent months include The Beauty Tech Group, small business lender Shawbrook and tinned tuna firm Princes.

Peel Hunt added that deal activity had “continued at pace” throughout its first half, with 60 transactions announced across the market during that time and 10 active bids for FTSE 350 companies, as at the end of September.

Half-year results for Peel Hunt showed pre-tax profits jumped to £11.5 million in the six months to September 30, up from £1.2 million a year earlier, as revenues lifted 38.3%.

Peel Hunt said its workforce has been cut by nearly 10% since the end of March under an ongoing savings drive, with full-year underlying fixed costs down by around £5 million.

Steven Fine, chief executive of Peel Hunt, said: “The second half has started strongly, with the group continuing to play leading roles across both mergers and acquisitions and equity capital markets mandates.”

Business

Gross GST collections for November stand at over Rs 1.70 lakh crore; up 0.7 per cent – The Times of India

GST collections: The Gross Goods and Services Tax (GST) collections for the month of November came in at over Rs 1.70 lakh crore. This is a rise of 0.7%, according to official data.SBI Research in a report in November had estimated that the gross domestic GST collections may come around Rs 1.49 lakh crore for November 25 (returns of October 25 but filed in Nov’25), a YoY growth of 6.8%.“Coupled with Rs 51,000 crore of IGST and cess on Import, the November GST collections thus could cross Rs 2.0 lakh crore, driven by the peak festive season demand led by lower GST rate and increased compliance while most of states experience positive gains,” SBI Research had said.This story is being updated

Business

Key Financial Deadlines That Have Been Extended For December 2025; Know The Last Date

New Delhi: Several crucial deadlines have been extended in December 2025, including ITR for tax audit cases, ITR filing and PAN and Aadhaar linking. These deadlines will be crucial in ensuring that your financial affairs operate smoothly in the months ahead.

Here is a quick rundown of the important deadlines for December to help you stay compliant and avoid last-minute hassles.

ITR deadline for tax audit cases

The Central Board of Direct Taxes has extended the due date of furnishing of return of income under sub-Section (1) of Section 139 of the Act for the Assessment Year 2025-26 which is October 31, 2025 in the case of assessees referred in clause (a) of Explanation 2 to sub-Section (1) of Section 139 of the Act, to December 10, 2025.

Belated ITR filing deadline

A belated ITR filing happens when an ITR is submitted after the original due date which is permitted by Section 139(4) of the Income Tax Act. Filing a belated return helps you meet your tax obligations, but it involves penalties. You can only file a belated return for FY 2024–25 until December 31, 2025. However, there will be a late fee and interest charged.

PAN and Aadhaar linking deadline

The Income Tax Department has extended the deadline to link their PAN with Aadhaar card to December 31, 2025 for anyone who acquired their PAN using an Aadhaar enrolment ID before October 1, 2024. If you miss this deadline your PAN will become inoperative which will have an impact on your banking transactions, income tax return filing and other financial investments.

-

Sports1 week ago

Sports1 week agoWATCH: Ronaldo scores spectacular bicycle kick

-

Entertainment1 week ago

Entertainment1 week agoWelcome to Derry’ episode 5 delivers shocking twist

-

Politics1 week ago

Politics1 week agoWashington and Kyiv Stress Any Peace Deal Must Fully Respect Ukraine’s Sovereignty

-

Business1 week ago

Business1 week agoKey economic data and trends that will shape Rachel Reeves’ Budget

-

Tech6 days ago

Tech6 days agoWake Up—the Best Black Friday Mattress Sales Are Here

-

Politics1 week ago

Politics1 week ago53,000 Sikhs vote in Ottawa Khalistan Referendum amid Carney-Modi trade talks scrutiny

-

Fashion1 week ago

Fashion1 week agoCanada’s Lululemon unveils team Canada kit for Milano Cortina 2026

-

Tech6 days ago

Tech6 days agoThe Alienware Aurora Gaming Desktop Punches Above Its Weight