Business

The firms looking to destroy harmful ‘forever chemicals’

Technology Reporter

374Water

374Water“There’s a lot of destruction that needs to be done,” sums up Parker Bovée of Cleantech Group, a research and consulting firm.

He is referring to PFAS (Perfluoroalkyl and Polyfluoroalkyl Substances), also known as “forever chemicals”.

These man-made chemicals can be found in items such as waterproof clothing, non-stick pans, lipsticks and food packaging.

They are used for their grease and water repellence, but do not degrade quickly and have been linked to health issues such as higher risks of certain cancers and reproductive problems.

The extraordinarily strong carbon-fluorine bonds they contain gives them the ability to persist for decades or even centuries in nature.

PFAS can be detected and removed from water and soil and then concentrated into smaller volumes of high strength waste.

But what to do with that waste?

Currently, concentrated PFAS waste is either put in long-term storage which is expensive, or incinerated (often incompletely, leading to toxic emissions), or sent to landfills for hazardous waste.

But now clean-tech companies are bringing techniques to market that can destroy them.

These are being tested in small-scale pilot projects with potential customers including some industrial manufacturers, municipal wastewater treatment plants and even the US military.

There’s a “large and growing” market opportunity for PFAS destruction companies notes Mr Bovée.

While it is mostly currently centred in the US, others are dipping their toes, he says.

In the UK, funding for water companies to look into PFAS destruction has been provided by water regulator Ofwat, with Severn Trent Water leading a project to examine the potential technologies and suppliers.

One factor driving the market forward in the US is legal risk. Thousands of lawsuits claiming PFAS-related contamination and harm have been filed with some large chemical manufacturers, notably 3M, having already paid out billions in class-action settlements.

Regulation is also beginning to tighten worldwide.

Legal limits for two PFAS in drinking water are now scheduled to take effect in the US in 2031.

PFAS remains a bipartisan issue, says Mr Bovée, and many expect that future US regulation will expand beyond drinking water to cover industrial discharge and other sources.

The EU also has legal limits for PFAS in drinking water, which member states must begin enforcing from next year.

Axine Water Technologies

Axine Water TechnologiesThere are a variety of technologies for destroying PFAS – each with their own advantages and limitations.

According to Mr Bovée, one technology that is almost commercially ready is electrochemical oxidation (EO) technology.

Electrodes are placed in water contaminated by PFAS and a current is passed through, resulting in the chemicals’ breakdown.

While energy intensive, it doesn’t require high temperature or pressure, and is easy to operate and integrate into existing treatment systems for concentrating PFAS, says Mark Ralph, CEO of Canadian-based start-up Axine Water Technologies.

Last year, following a successful pilot project, it sold its first commercial-scale unit to a Michigan-based producer of automotive components. It is now up and running and the customer is planning to purchase additional systems for other sites.

374Water

374WaterAnother technology not far behind is Supercritical Water Oxidation (SCWO).

It relies on heating and pressurising water to such a high degree that it enters a new state of matter: a so-called supercritical state. When the PFAS waste stream is introduced, it breaks the carbon-fluorine bonds.

One advantage is that it can process both solid and liquid PFAS waste, says Chris Gannon, CEO of North Carolina-based 374Water.

He says his technology can even destroy PFAS in plastics if they are ground up.

It can be expensive to buy and maintain – the process is so intense it requires a complex reactor and regular cleaning. But it can be more cost effective if the PFAS is first concentrated before it enters the process.

Currently the City of Orlando in Florida is testing 374Water’s technology at its largest wastewater treatment plant.

The City is trying to get ahead of the curve, explains Alan Oyler, its special projects manager for public works.

Levels of PFAS in sewage sludge aren’t currently regulated, but he expects them to be in the future.

So far, Mr Oyler is pleased with the destruction capability he has seen, but is also waiting to see how reliable the system is.

The scale of 374Water’s current technology is small: it can handle just a fraction of the tonnes of wet sludge the facility produces daily.

But the company is in the process of scaling up, and Mr Oyler imagines in a few years it will be able to handle all the facility’s material “ready for when the regulations require”.

Other technologies on their way to being commercially ready include hydrothermal alkaline treatment (HALT), which uses high temperature, high pressure, and an alkaline chemical to destroy PFAS; and plasma-based technology, which involves making an ionized gas (called a plasma) to attack and degrade the PFAS molecules.

Aquagga

AquaggaYet there is one potential issue with the technologies now coming through, says Jay Meegoda, a professor of civil and environmental engineering at the New Jersey Institute of Technology: nasty PFAS degradation byproducts.

For example, in the case of EO, highly corrosive hydrogen fluoride vapor. Each needs a “complete study” accounting for all their inputs and outputs, he says.

The companies have claimed they either don’t produce PFAS degradation products or deal with them adequately.

One important partner for many of the PFAS destruction companies in testing their technologies in the real world has been the US Department of Defence (DOD).

PFAS contamination at US military sites is a big, below-the-radar problem. It stems particularly from the use of older formulations of firefighting foam, used for example during training exercises or emergencies, but other routes too such as the cleaning of military equipment.

More than 700 sites are known or suspected to be contaminated, posing a threat to surrounding communities. A judge recently cleared the way for PFAS contamination and harm lawsuits against the military to proceed.

Clean up efforts are where the destruction companies could come in, and projects have been undertaken or are under way at various sites to assess the performance and cost effectiveness of many of their solutions.

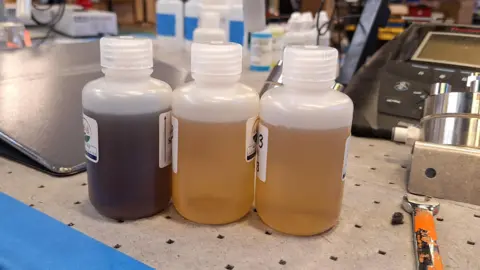

One start-up, Aquagga, which specialises in HALT technology, recently completed a demonstration project for the DOD which involved destroying a firefighting foam mixture amongst other concentrated PFAS-containing liquids.

Immense volumes of the foam are currently stockpiled in all sorts of places, not just at military sites.

Like others, Aquagga sees a big opportunity over the next few years for both destroying the foam and remediating the environmental damage associated with its use.

And outside the military, there’s a tantalizing new PFAS waste stream on the horizon. The US is actively expanding domestic computer chip manufacturing – a process that uses PFAS in massive amounts. “We can destroy that,” says Mr Gannon, of 374Water.

Business

Those with MGNREGA cards to get work during transition to G RAM G Act – The Times of India

NEW DELHI: People with job cards assigned under Mahatma Gandhi National Rural Guarantee Scheme will be able to get work without disruption when transition takes place to new rural employment framework under Viksit Bharat-Guarantee for Rozgar and Aajeevika Mission (Gramin) Act.Even though exact timeframe is not known yet, rural development ministry officials said the VB-G RAM G scheme will come into force in the coming financial year after the Centre frames and notifies the rules. After govt notifies the Act’s commencement date, states will get six months to make their schemes to enable implementation of the law.To ensure there is no disruption and job guarantee is upheld during transition from MGNREGA, it has been proposed to enable workers to use the same job cards issued under MGNREGA with Aadhaar-based eKYC.The officials said that as of now, around 75% of job cards have been verified with eKYC under the ongoing scheme. Moreover, ongoing projects under MGNREGA, if incomplete when the transition happens to the new scheme, would stay on course.Meanwhile, work is on to frame rules, lay out regulations on normative allocations, fund flow plan, IT framework, a national-level steering panel and social audits.Under the new law, focus will be on transparency to weed out leakages and duplicacy of work,the social audit system will be strengthened, and technology leveraged to create systems to establish work progress, timely wage payment and accountability through ‘e-measurement’ books, sources said. Demand for work will have to be entered on a digital platform. Officials made it clear the new law in no way interferes with demand-driven character of the scheme.

Business

Gurugram Attracts Rs 86,588 Crore In Real Estate Investments In 2025 As RERA Clears 131 Projects

Last Updated:

Alongside rising investments, Gurugram RERA strengthened regulatory oversight to safeguard homebuyer and investor interests

Gurgaon Real Estate (Representative Image)

Gurugram emerged as one of India’s top real estate investment destinations in 2025, with projects worth Rs 86,588 crore receiving regulatory approvals during the year, according to data from the Gurugram Real Estate Regulatory Authority (Gurugram RERA).

Market observers said the numbers reflect strong investor confidence in the NCR’s largest commercial and residential hub.

Gurugram RERA registered 131 projects in calendar year 2025, representing development potential of 35,455 units across housing and commercial segments.

A striking feature of the data was the dominance of large-ticket projects. Just 28 major developments accounted for investments worth Rs 59,360 crore, highlighting the growing influence of institutional capital and large developers in shaping Gurugram’s property market.

Residential assets continued to attract the bulk of investment interest. Of the total units approved, 31,455 were residential, underscoring sustained end-user demand and long-term confidence in the city’s housing fundamentals.

According to Authority data, the residential mix included 17,405 group housing units, 5,720 mixed land use units, 4,040 residential floor units, 2,122 affordable group housing units, 1,954 units under the Deen Dayal housing scheme, and 214 residential plotted colony units.

Market observers said this diversified supply pipeline indicates capital deployment across both premium and mass segments, helping reduce concentration risk and deepen market resilience.

On the commercial side, Gurugram RERA approved about 4,000 commercial units, of which 168 were dedicated to IT parks, reinforcing Gurugram’s position as a preferred hub for technology firms and Global Capability Centres.

Analysts noted that the combination of office-led employment growth and residential expansion continues to make Gurugram attractive for long-term capital deployment.

Industry experts said the scale of investments approved in 2025 highlights Gurugram’s ability to attract capital despite global uncertainty, supported by infrastructure growth, a strong corporate base and an improving regulatory environment.

“With a large pipeline of approved projects and sustained interest from developers and institutional investors, Gurugram is expected to remain a key real estate investment destination in the coming years,” a Gurugram-based real estate expert said.

Tighter regulatory checks

Alongside rising investments, Gurugram RERA strengthened regulatory oversight to enhance transparency and safeguard homebuyer and investor interests.

“These steps included stricter scrutiny of developer submissions, mandatory site inspections by domain experts, and public consultation through mandatory notices before project registration,” an Authority official said.

January 16, 2026, 07:44 IST

Read More

Business

National Startup Day 2026: How India’s Startups Are Shaping The Future

Last Updated:

National Startup Day highlights India’s thriving startup ecosystem, celebrating innovation, entrepreneurship and job creation driven by founders, unicorns and Startup India mission

National Startup Day 2026 honours Indian startups, entrepreneurs and innovators driving economic growth and job creation.

National Startup Day 2026: India’s startup ecosystem has evolved into one of the world’s most vibrant and promising innovation hubs. To recognise the contribution of entrepreneurs, founders and startups transforming ideas into impactful solutions, National Startup Day is observed every year on January 16 across the country.

Launched by Prime Minister Narendra Modi in 2022, the day celebrates visionary entrepreneurs who play a crucial role in economic growth, employment generation and technological advancement.

National Startup Day serves as a reminder that innovation, backed by determination and policy support, can reshape society and create global impact.

National Startup Day 2026 Theme

The official theme for National Startup Day 2026 is yet to be announced. However, the core focus areas are expected to revolve around:

- Innovation and emerging technologies

- Entrepreneurship and leadership

- Self-reliance (Atmanirbhar Bharat)

- Startup India Mission

- Youth empowerment

- Job creation

How Startups Are Shaping India’s Future

India currently ranks as the third-largest startup ecosystem globally, with over 1.59 lakh startups recognised by the Department for Promotion of Industry and Internal Trade (DPIIT) as of early 2025. Backed by 100+ unicorns, the ecosystem continues to grow rapidly.

Metro cities such as Bengaluru, Hyderabad, Mumbai and Delhi-NCR lead this expansion, while Tier-2 and Tier-3 cities are emerging as new innovation centres, adding diversity and scale to India’s entrepreneurial journey.

Startups across fintech, edtech, health-tech, e-commerce and deep-tech are addressing real-world challenges and gaining global recognition. Technologies like artificial intelligence, blockchain and IoT are increasingly driving innovation, according to Startup India ecosystem reports.

Industry-Wise Startup Impact

DPIIT-recognised startups have generated over 16.6 lakh direct jobs across sectors as of October 31, 2024, strengthening India’s employment landscape.

- IT Services: 2.04 lakh jobs

- Healthcare & Life Sciences: 1.47 lakh jobs

- Commercial & Professional Services: 94,000 jobs

Through the Startup India initiative, the government continues to focus on skill development, funding access, ecosystem collaboration and global outreach.

Key Initiatives Under Startup India

- Capacity building and mentorship

- Outreach and awareness programmes

- Ecosystem development events

- International exposure and global linkages

- Collaboration between startups, corporates and institutions.

January 16, 2026, 07:00 IST

Read More

-

Politics1 week ago

Politics1 week agoUK says provided assistance in US-led tanker seizure

-

Entertainment1 week ago

Entertainment1 week agoDoes new US food pyramid put too much steak on your plate?

-

Entertainment1 week ago

Entertainment1 week agoWhy did Nick Reiner’s lawyer Alan Jackson withdraw from case?

-

Business1 week ago

Business1 week agoTrump moves to ban home purchases by institutional investors

-

Sports5 days ago

Sports5 days agoClock is ticking for Frank at Spurs, with dwindling evidence he deserves extra time

-

Sports1 week ago

Sports1 week agoPGA of America CEO steps down after one year to take care of mother and mother-in-law

-

Tech3 days ago

Tech3 days agoNew Proposed Legislation Would Let Self-Driving Cars Operate in New York State

-

Business1 week ago

Business1 week agoBulls dominate as KSE-100 breaks past 186,000 mark – SUCH TV